- Font Size

-

- Small

- Medium

- Large

Application Example

MONITOUCH V9 series: Introducing V9xxxixD-U800

About Explosion Proof

What is explosion-proof equipment?

a system for testing compliance with explosion-proof equipment standards, in 1996. In hazardous locations, explosion-proof equipment that complies with the standard must be used.

In atmospheres where flammable or pyrophoric gases may be present, explosion-proof equipment should be used.

*1 International Electrotechnical Commission (IEC) is the organization for the preparation

and publication of international standards for all electrical, electronic and related technologies.

There are 89 member countries worldwide (as of March 2025).

https://www.iec.ch/dyn/www/f?p=103:5:0

What are hazardous areas?

Hazardous areas are classified into 3 zones based on the explosion risk by IEC60079.

| Zone0: | An area in which an explosive gas atmosphere is present continuously or for long periods. (Above the liquid level of combustible gas, etc.) |

| Zone1: | An area in which an explosive gas atmosphere is likely to occur occasionally in normal operation. (Gas and steam discharge areas and near injection openings) |

| Zone2: | An area which becomes hazardous in case of an accident or some unusual operating condition and is close to Zone1. |

MONITOUCH V9 Series: Explosion-proof Model *2

Line-up

MONITOUCH V9 series (Explosion-proof Model) is complied with the IECEx international standard, ATEX Directive (EU explosion-proof standard), Taiwan TS Mark, and Korea KCs certification *3.

| *2 | Install in an explosion-proof certified enclosure with appropriate explosion-proof construction, such as Ex ec IIC Gc, Ex eb IIC Gc, and Ex nA IIC Gc. |

| *3 | Each country may have its own certification system (explosion-proof, EMC, etc.). Please check the certification system of each country before using the product. |

Explanation of explosion-proof standards

According to the definition of explosion-proof standard, MONITOUCH V9 series (Explosion-proof Model) is described as below.

| Ex nA IIc T5 Gc |

| Ex ec IIc T5 Gc |

| Mark | Content | Description |

|---|---|---|

| Ex | Explosion-proof | Indicates compliance with explosion-proof. Ex is always indicated. |

| nA | Type of protection | Non-incendive explosion-proof. A device designed to prevent the arcs or sparks that could cause ignition during normal operation. |

| ec | Increased safety explosion-proof. A device that does not generate sparks, designed with increased safety by suppressing temperature rise and reinforcing insulation. | |

| IIc | Atmosphere group | Available for use in explosive gas atmospheres (e.g., factories) other than mines, and in explosive gas atmospheres with an explosion class of 3 or lower. |

| T5 | Temperature class | Available for use in atmospheres where permissible surface temperature is 100 degree C and the ignition temperature of any explosive gas present exceeds 100 degree C. |

| Gc | Equipment protection level (EPL) | Equipment with enhanced protection levels, available for use in Zone 2. |

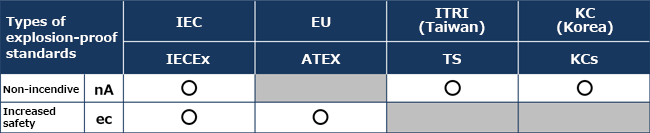

・Compliant type of protection for Each Explosion-Proof Standard

Industries in demand

| Oil and Gas Industry | Pharmaceutical and Chemical Industry |

|---|---|

|  |

| - Oil and gas refineries - Oil complexes | - Pharmaceutical factories - Paint factories |

| - Gas storage tanks | - Chemical fertilizer Plants |

| - Oil and gas supply facilities | - Soap and detergent factories |

| - Oil and gas power plants | |

| Manufacturing Industry | Semiconductor Industry |

|  |

| - Rubber product manufacturing plants | Semiconductor manufacturing plants |

| - Automobile plants | - Cleaning process |

| - Plastic product manufacturing plants | - Film deposition process |

| - Printing factories | - Resist coating |

| - Etching process | |

| - Resist stripping process | |

| etc. |

In addition, explosion-proof equipment is required in various places, such as where volatile solvents

are present (stored) and the volatilized gas becomes flammable.

Precautions for MONITOUCH V9 series (Explosion-proof Model)

- Mounting angle is 90 degrees.

- Audio port cannot be used. (Usable except Zone2)

- 8 mounting brackets are required for the installation of V9120iSD-U800. (4pcs for standard model)

MONITOUCH Application Introductions

Paperless

PDF file output function (Extended data sheet printing)

| - | It is possible to save the pre-defined format as PDF file into an SD card. |

| - | You can place numerical displays of PLC values, graphs and images in the printing format. |

| - | Page insertion option is available to output in one file. (First in industry) (*4) Direct printing from a network printer is also possible. |

MONITOUCH EXPRESS Issue No. 70: V9 series - FTP client function

MONITOUCH EXPRESS Issue No. 92: Improving Operation by Outputting PDFs Using the V9 Series Data Sheet Screen

MONITOUCH EXPRESS Issue No. 94: V9 Series Network Printer Function

*4 According to our own research.

Monitoring by tablet devices

VNC server function

| - | VNC server function is equipped in all V9 models as standard, so no additional license is required. |

| - | You can monitor and operate V9 series from a remote location by installing a VNC client app on a tablet device. (Operation can be prohibited by settings) |

MONITOUCH EXPRESS Issue No. 121: V9 Ethernet application idea

Remote monitoring

VPN server function

| - | VPN router function is built in all V9 models as standard. |

| - | “Easy”, “low cost” and “safe and secure” remote access can be established. |

| - | By using routing function, remote connection with PLC or other devices connected to V9 series via Ethernet is also available. |

MONITOUCH EXPRESS Issue No. 48: V9 series - VPN feature (Part1)

MONITOUCH EXPRESS Issue No. 50: V9 series - Web Machine Interface (VPN Remote Access Service)

MONITOUCH EXPRESS Issue No. 77: V9 series - Remote Maintenance