- Font Size

-

- Small

- Medium

- Large

- Home >

- TECHNOSHOT >

- TS1000 series(discontinued) > Products/Features >

- Features of TS1000 Series

Features of TS1000 Series

- Versatile Functions

- Configuration Software [V-SFT]

- Component Parts

Functions

Convenient functions that meet the requirements of production sites

Offers High-level easy to use functions and a remote control with dedicated software

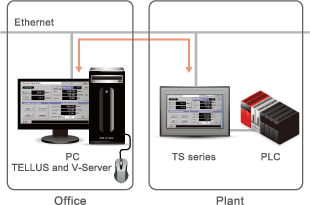

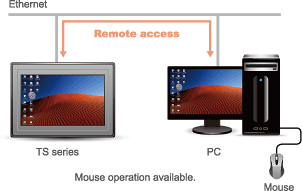

01Remote Maintenancei series only

Data in a TS panel can be monitored and controlled from a remote office at low cost.

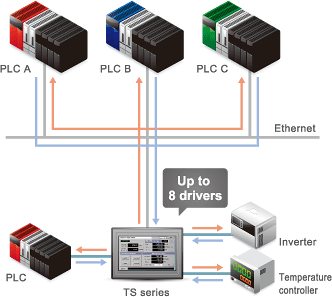

028-Way Communication

Communication is available with up to eight kinds of devices consisting of PLCS and peripherals of different manufacturers through Ethernet or serial connection.

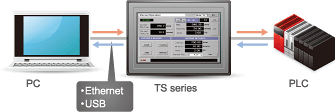

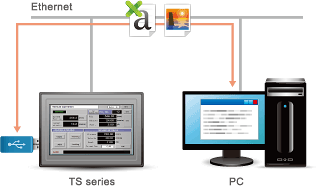

03Path-through Programming

TECHNOSHOT allows you to write/read PLC ladder programs to/from your PC through Ethernet or USB connection.

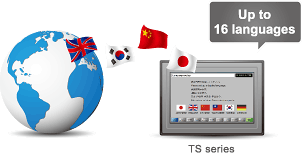

04Multilanguage

You can change the language displayed on the screen to one of 16 languages. You need not manage files for each language.

- Compatible language fonts:

- Japanese, English/ Western European, Chinese (traditional and simplified), Korean, Central European, Cyrillic, Greek, Turkish and Baltic.

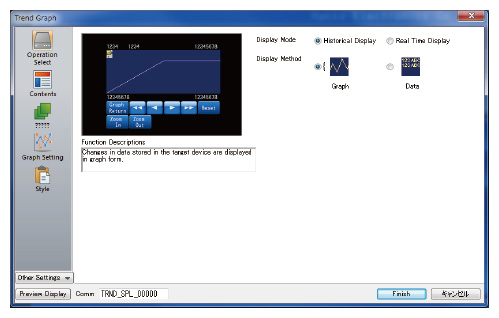

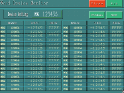

05Trend Sampling

Various kinds of data, which change from moment to moment, are recorded chronologically and shown in a trend graph.

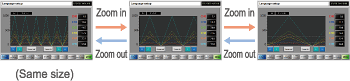

" Zoom Display

Magnification of a specified area allows you to check the waveform of the trend graph specifically.

06Remote Connection from Tablet devicesi series only

- VNC Server Function

- TS1000 series are equipped with VNC server function. It is possible to monitor and operate the equipment remotely from PC via wired LAN. In addition, you can also access from your tablet devices by connecting TS1000 series to wireless router.

07Remote Desktop*i series only

Screen on the server PC can be displayed and operated on a TS panel through Ethernet.

*License required.

08FTP Serveri series only

Data in the USB thumb drive fitted to the TS panel can be read or written from/to the PC via FTP client tool.

Operation history is saved as a binary file.

No need to worry about falsification of data.

09Operation Log

You can view log data for operations such as pushing of buttons and entering of values to check the “who/when/what/how” history and analyze the causes of failure.

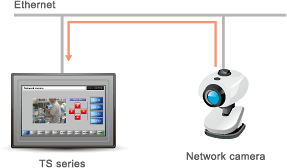

10Network Camerai series only

Images shot by network cameras can be displayed on a TS panel via Ethernet, which enables monitoring of production lines.

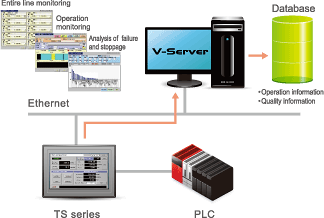

11MESi series only

Various types of information such as production results and causes of failure and stoppage can be collected and saved in the database of the server through a TS panel and V-server.

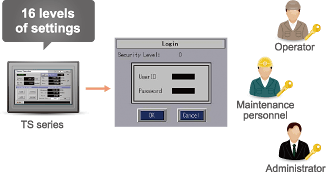

12Security Function

By setting a function limit according to the user level, a high-security environment can be established.

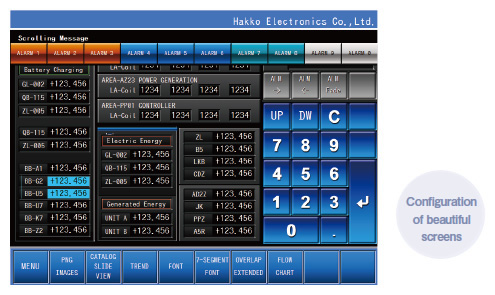

Configuration of Easy-to-view Screens

The number of picture icons has been increased, and the icons with plain design have been added.

Pick from the wide range of ready-made icons for sophisticated representation.

01Simple icons added

Popular simple icons that are used widely on smartphones have been introduced.

02Increased picture icons

The number of the picture icons has been increased.

Upgraded Operability

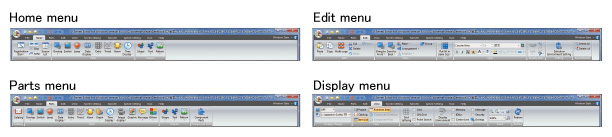

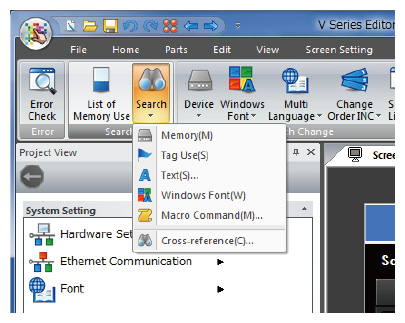

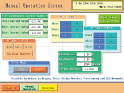

01Ribbon Menu

The ribbon-shaped menu bar is available. Enlarged icons are easily visible also improves the operability remarkably.

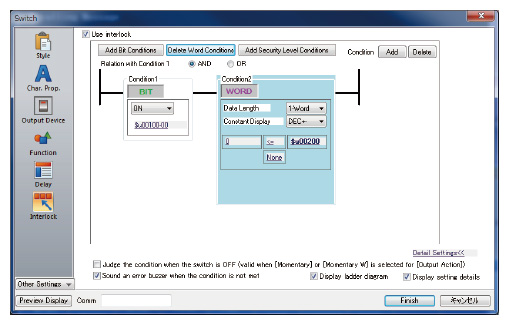

02Ladder Diagram for Interlock

Interlocking operations can be set on the ladder diagram, which makes it easy to grasp the settings and set multiple conditions.

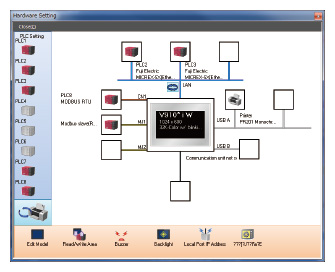

03Graphic Indication of System Configuration

The improved hardware setting screen makes it easy to grasp exactly how devices are connected together in the system.

04Docking Windows

The project view windows and item view windows can be docked or floated easily.

05Integration of Search menu

The search menu, which used to be displayed separately, have now been integrated for easy operation.

Facilitation of Screen Configuration

01Guided Setting Process

With the help of the clear instructions in the dialog, setting can be conducted smoothly and collectively.

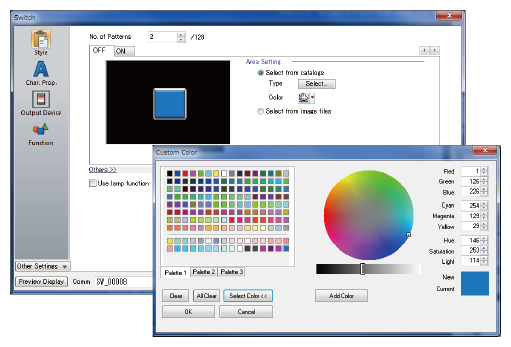

02A Wider Range of Colors for Component Parts

65,536 colors are available for components parts.

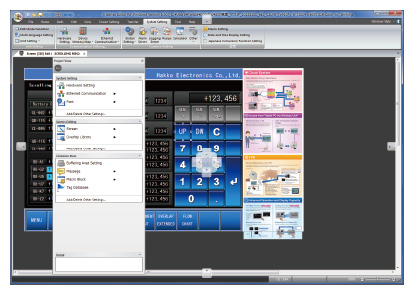

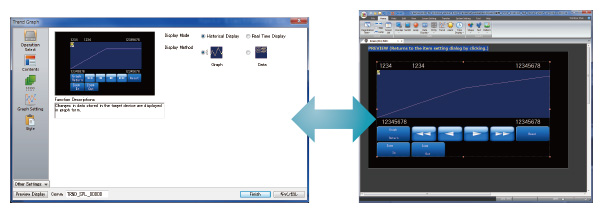

03Visualization of Setting

Set conditions can be confirmed on the preview screen before completing setting. By switching the preview screen and setting dialog, the setting can be confirmed easily even on a PC with low resolution.

Component Parts

Integrated parts to facilitate screen configuration

Creating sophisticated screens by selecting parts with desired functions and macros.

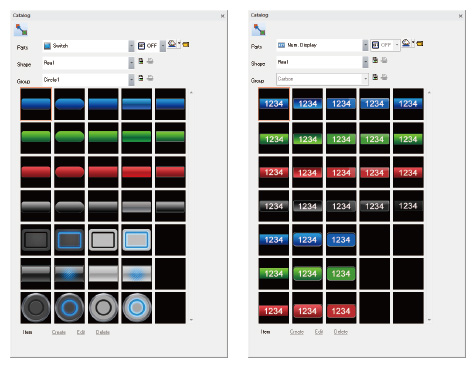

01Selection from Parts Library

You can easily create screens by selecting component parts from the parts library and arranging them.

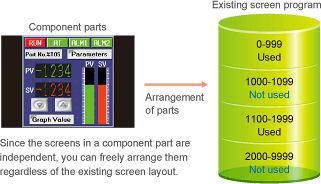

02Addition to the Existing Program

Component parts can be easily added to the unused area in the existing screen program.

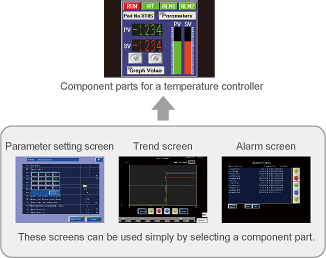

03Screens Integrated in a Part

A component part consisting of some screens facilitates quick screen configuration.

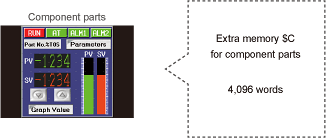

04No Worry about Memory Shortage

Extra memory is provided for component parts separately from the memory for existing screens.

05A variety of Compornent Parts

Component parts with various functions can be selected from the parts list to create screens according to your purpose easily.

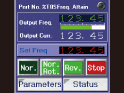

Temperature controller

Screen for monitoring and parameter setting of temperature controllers

Inverter

Screen for monitoring and parameter setting of inverters

Robot controller

Screen for monitoring and operation setting of robots

I/O Monitor

Screen to monitor PLC I/O

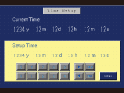

Calendar setting

Screen for date setting of PLCs

TECHNOSHOT

- Lineup

- TS2000 series

- TS1000 Smart series

- TS1000 series(discontinued)