- Font Size

-

- Small

- Medium

- Large

- Home >

- TECHNOSHOT >

- TS2000 series > Products/Features >

- Features of TECHNOSHOT Series

Features of TECHNOSHOT Series

- Versatile Functions

- Configuration Software [V-SFT]

- Component Parts

Functions

Convenient functions that meet the requirements of production sites

Offers High-level easy to use functions and a remote control with dedicated software

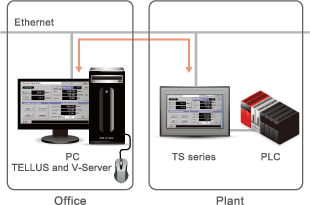

01Remote Maintenancei series only

Data in a TS panel can be monitored and controlled from a remote office at low cost.

Application software for connecting your office and production sites at low cost

This software enables collection and management of product ion site information via the Internet in real time from your office in Japan or overseas.

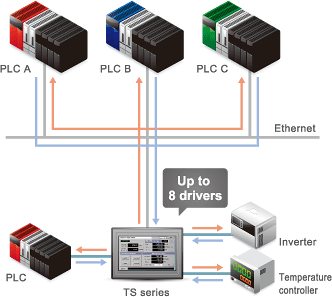

028-Way Communication

Communication is available with up to eight kinds of devices consisting of PLCS and peripherals of different manufacturers through Ethernet or serial connection.

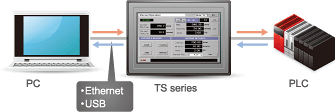

03Path-through Programming

TECHNOSHOT allows you to write/read PLC ladder programs to/from your PC through Ethernet or USB connection.

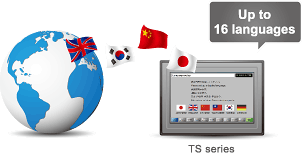

04Multilanguage

You can change the language displayed on the screen to one of 16 languages. You need not manage files for each language.

- Compatible language fonts:

- Japanese, English/ Western European, Chinese (traditional and simplified), Korean, Central European, Cyrillic, Greek, Turkish and Baltic.

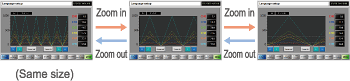

05Trend Sampling

Various kinds of data, which change from moment to moment, are recorded chronologically and shown in a trend graph.

" Zoom Display

Magnification of a specified area allows you to check the waveform of the trend graph specifically.

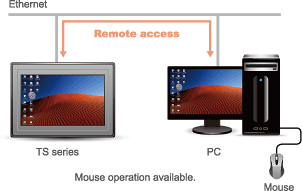

06Remote Desktop*i series only

Screen on the server PC can be displayed and operated on a TS panel through Ethernet.

*License required.

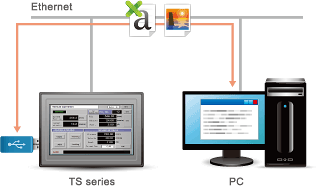

07FTP Serveri series only

Data in the USB thumb drive fitted to the TS panel can be read or written from/to the PC via FTP client tool.

Operation history is saved as a binary file.

No need to worry about falsification of data.

08Operation Log

You can view log data for operations such as pushing of buttons and entering of values to check the “who/when/what/how” history and analyze the causes of failure.

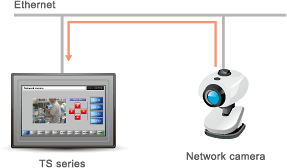

09Network Camerai series only

Images shot by network cameras can be displayed on a TS panel via Ethernet, which enables monitoring of production lines.

10MESi series only

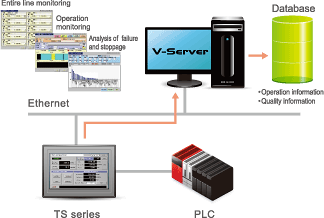

Various types of information such as production results and causes of failure and stoppage can be collected and saved in the database of the server through a TS panel and V-server.

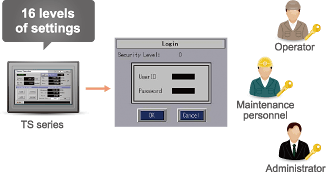

11Security Function

By setting a function limit according to the user level, a high-security environment can be established.

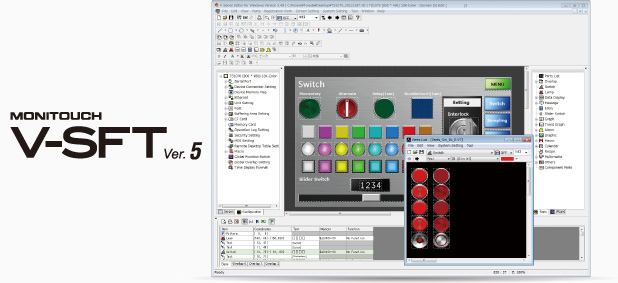

Configuration software

Easy screen configuration

Facilitates screen configuration and maintenance with various functions

| PC | PC/AT compatibles with Windows |

|---|---|

| OS | Windows98SE/ Me/ NT Version4.0/ 2000/ XP/ XP 64 Edition/ Vista 32bit/ Vista 64bit/ Win7 32bit/ Win7 64bit/ Win8 32bit/ Win8 64bit*1 |

| CPU | Pentium3 800MHz or higher (Pentium4 2.0GHz or higher is recommended.) |

| Memory | 512MB or more |

| Hard disk | For installation: 1.8GB or more space required |

| CD-ROM disk drive | 24 times or faster |

| Display | Resolution of 1,024 × 768 (XGA) or higher |

| Color indication | High color (16 bit) or higher |

| Note | Microsoft.NET Framework4.0 or 4.5 (Framework4.0 will be installed automatically in Windows XP*2/ Vista*2/ 7 PCs that do not have NET Framework4.0 or 4.5 already installed.) |

- *1 For installing in Windows NT Version4.0/ 2000/ XP/ XP 64 edition/ Vista 32bit/ Vista 64bit/ Win7 32bit/ Win7 64bit/ Win8 32bit / Win8 64bit, administrator authorization is required.

- *2 It is necessary to update the OS to Windows XP Service Pack 3 or later or Windows Vista Service Pack 1 or later in order to install Microsoft .NET Framework 4.0.

- *TECHNOSHOT is compatible with Ver.5.4.28.0 or later.

01Emulator

V-SFT Ver.5 allows debugging of the screen program on your PC.

02Auto Resizing

Automatic resizing from QVGA (320×240) to WVGA (800×480). Previous screen program can be used without change.

03Function Switches Display*

Function switches on the previous models can be added to the screen, and the screen program for the function switches can be used as well.

*Two-step switch operation is not available.

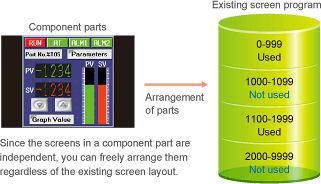

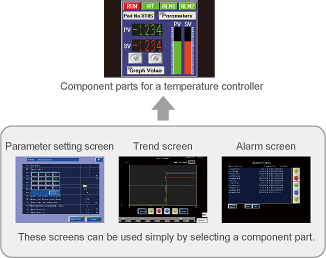

Component Parts

Integrated parts to facilitate screen configuration

Creating sophisticated screens by selecting parts with desired functions and macros.

01Selection from Parts Library

You can easily create screens by selecting component parts from the parts library and arranging them.

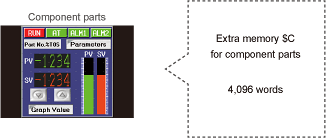

02Addition to the Existing Program

Component parts can be easily added to the unused area in the existing screen program.

03Screens Integrated in a Part

A component part consisting of some screens facilitates quick screen configuration.

04No Worry about Memory Shortage

Extra memory is provided for component parts separately from the memory for existing screens.

05A variety of Compornent Parts

Component parts with various functions can be selected from the parts list to create screens according to your purpose easily.

Temperature controller

Screen for monitoring and parameter setting of temperature controllers

Inverter

Screen for monitoring and parameter setting of inverters

Robot controller

Screen for monitoring and operation setting of robots

I/O Monitor

Screen to monitor PLC I/O

Calendar setting

Screen for date setting of PLCs

TECHNOSHOT

- Lineup

- TS2000 series

- TS1000 Smart series

- TS1000 series(discontinued)