- Font Size

-

- Small

- Medium

- Large

- Home >

- V8 >

- Products/Features > 8-way communication >

- 8-way communication

8-way communication

- Network

- Examples

Network

Connectable with up to eight different kinds of automation devices and different manufacturers' PLCs

8-way communication

8-way communication enables connection among a V8 and up to eight kinds of devices consisting of PLCs and peripherals of different manufacturers.

- Simultaneous communication and data transfer with eight kinds of devices

- Simultaneous monitoring and operation of multiple PLCs and peripherals

- Linkage between a V8 and various devices on the LAN network using the gateway function

Network Examples

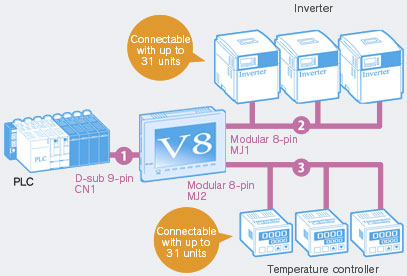

Example 1 Serial connection (three ports)

Making a network linked with various automation devices

PLCs and peripherals of up to three kinds of units can be connected by serial connection. Even though two or more types of temperature controllers and inverters are used, they can be connected with one V8.

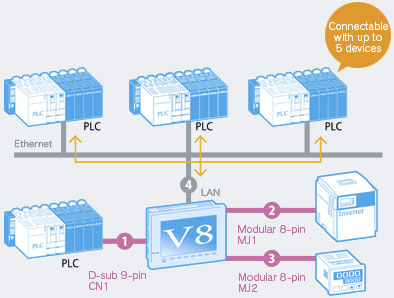

Example 2 Serial connection and Ethernet

Integrated management of up to eight kinds of devices

In addition to conventional connection with temperature controllers and PLCs via 2-way serial communication, connection via Ethernet is possible.

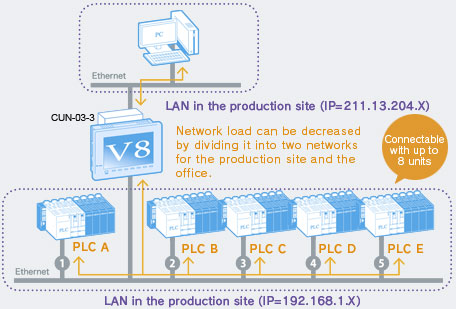

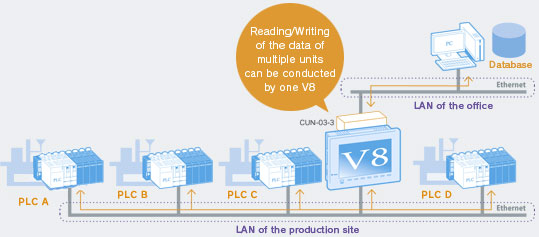

Example 3 Ethernet “First in Industry!”

Used as a gateway for different types of networks

V8 can connect with eight kinds of PLCs via Ethernet. In addition, the display can be used as a gateway with another network by adding an Ethernet port using an optional unit (CUN-03-3).

For example, data can be transferred between the production site and the office freely by using a V8. V8 works as the gateway of multiple networks of the production site and the office without increasing data load on the networks.

Examples

A variety of ingenious uses

8-way communication offers various functions

Network Examples

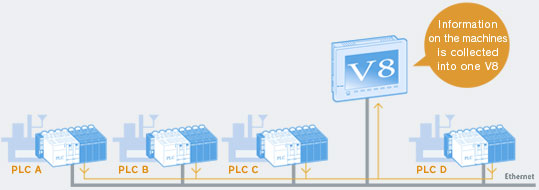

CASE 1 Analysis of trouble

Integrated management of different manufacturers' PLCs.

A production line that contains various manufacturers' equipment has various types of PLCs. By using 8-way communication, you can monitor the condition of all the PLCs through a V8 and analyze trouble at a remote place without visiting the site.

CASE 1Reading of production conditions and set data

Connectable with various kinds of equipment.

Even when the system consists of various kinds of equipment, it is easy to read and write the data of the individual units via 8-way communication. By using a V8 as a gateway, it is possible to connect with the office host system.

CASE 3Real-time indication of information

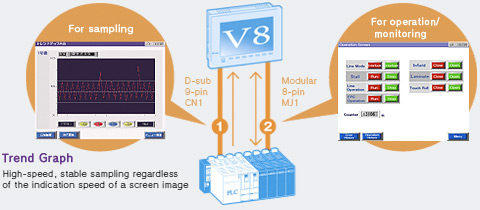

High-speed data sampling

The V8 is connected to the PLC via two communication lines: one for operation/monitoring, and the other for sampling, a setup that enables high-speed, stable sampling.